No Till Benefits: Boost Soil Health & Farm Profits

Written by

Paul Reynolds

Reviewed by

Prof. Samuel Fitzgerald, Ph.D.Advantages of No-Till: 47% increase in soil organic matter relative to conventional tillage

66% diesel savings because of reduced passes through the field in no-till

$15k-$45k carbon credits value for the 500 acres over five years

28-day drought tolerance versus 14-day drought tolerance of tilled fields with no-till

33% gain in profitability due to fuel/labor reduction and yield consistency

40-60% reduction in herbicides thanks to no-till cover crop allelopathy.

Article Navigation

The benefits of no-till come from its USDA-established practice of reducing soil disturbance. Traditional plow-based practices were used from the 1800s to the 1960's. No-till systems emphasize maintaining soil structure, reminiscent of the general movement by agriculture toward sustainability, instead of short-term practical benefits.

According to a report by The U.S. Department of Agriculture, approximately 21% of farming grounds in the U.S. have adopted no-till farming, which is a method associated with measurable improvements in soil organic matter and lower fuel costs. Farmers who utilize no-till farming techniques experience profit increases through decreased wear on farm equipment (by doing fewer field passes), and increased profits demonstrate that being good stewards of our agriculture environment can also be economically viable.

Soil Health Transformations

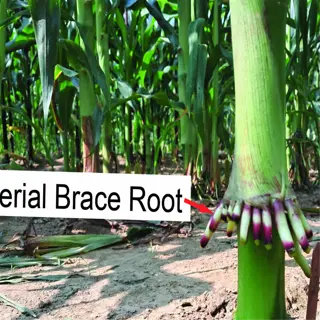

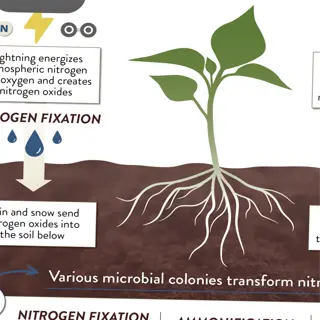

No-till systems offer positive impacts on soil health, resulting in increases in soil carbon levels to 2.8%, while tilled fields only result in soils up to 1.9%. The increase in soil carbon levels supports microbial communities that act, in a sense, as fertilizer factories. Healthier soils also provide increased resistance to erosion, as well as stronger root systems for crops such as corn and soybeans.

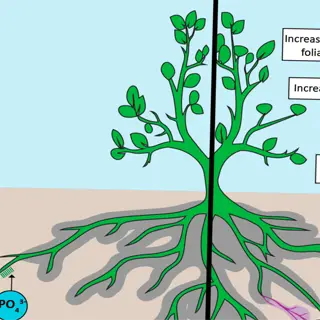

Underlying your boots, mycorrhizal networks flourish in no-till systems. Mycorrhizal networks are fungal highways that resemble a social communication system associated with wheat roots that mix nutrients among plants. Mycorrhizal networks are the result of living soil ecosystems where microbes interchange nitrogen and phosphorus for photosynthetic sugars produced by organisms above ground, in a nonstop underground economy.

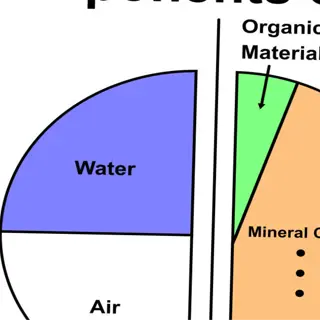

In no-till management, water holding capacity increases by 25mm (1 inch) per acre. This increased moisture footprint assists the crop during drought conditions in the summer. Fields with no-till management hold moisture like a sponge versus pooling or runoff, and therefore, can decrease irrigation needs by 40% during critical growth times.

Earthworms thrive in environments where the process of tillage is absent. Their burrows work to aerate the soil, while their nutrient-rich castings release nutrients trapped in organic matter. A no-till acre contains three times the number of earthworms compared to tilled ground, establishing a natural drainage system that helps avert waterlogged soils while enhancing the flow of oxygen to the roots of crops.

Earthworm Populations

- Fact: No-till systems host 3x more earthworms than tilled fields

- Impact: Create 11 km/ha (7 mi/ac) of bio-pores for water infiltration

- Measurement: 25-35 specimens per square meter average

- Benefit: Castings provide 2.2 lbs/acre (2.5 kg/ha) of available nitrogen

- Metric: 1500 kg/ha (1340 lb/ac) of surface casting production annually

- Role: Improve soil structure through continuous burrowing activity

Mycorrhizal Fungi

- Fact: 30% higher colonization rates in no-till systems

- Function: Extend root reach by 20 cm (8 inches)

- Benefit: Transfer 15-20% more phosphorus to crops

- Drought Role: Increase water uptake by 40% in dry spells

- Measurement: 450 µg/g biomass vs 300 µg/g in tilled soil

- Symbiosis: Exchange sugars for nutrients with plant roots

Soil Aggregate Stability

- Fact: No-till soils maintain 35-45% more stable aggregates

- Impact: Resist erosion during 50 mm/hr (2 in/hr) rainfall

- Measurement: 1.8-2.4 mm aggregate size in no-till systems

- Benefit: 25% higher resistance to wind erosion

- Metric: 80% water-stable aggregates vs 55% in tilled soil

- Role: Protect organic matter from microbial decomposition

Organic Matter Content

- Fact: Gains 0.23 tons/acre (0.52 tonnes/ha) carbon annually

- Impact: Stores 16,000 L/ha (1,700 gal/ac) extra water

- Measurement: 2.8% average vs 1.9% in tilled fields

- Benefit: Buffers pH fluctuations by 0.3-0.5 units

- Metric: 1.5x faster residue decomposition in no-till

- Function: Acts as nutrient reservoir for plant growth

Water Infiltration Rate

- Fact: 25 mm/hr (1 in/hr) vs 15 mm/hr (0.6 in/hr) in tilled

- Impact: Reduces surface runoff by 55-60%

- Measurement: 30-minute infiltration test results

- Benefit: 40% less irrigation required in arid regions

- Metric: 85% rainfall utilization efficiency

- Role: Recharges groundwater aquifers more effectively

Root Penetration Depth

- Fact: Corn roots reach 1.8 m (6 ft) vs 1.2 m (4 ft) in tilled

- Impact: Access 30% more subsoil nutrients

- Measurement: 50% deeper root systems on average

- Benefit: Withstand 3-week droughts without yield loss

- Metric: 25% higher trace mineral uptake

- Adaptation: Develop thicker root hairs in compacted layers

Microbial Diversity

- Fact: 1,200+ species vs 800 in tilled soil

- Impact: Break down 90% of crop residues in 8 months

- Measurement: 450 µg/g microbial biomass average

- Benefit: Suppress 40% of soil-borne pathogens naturally

- Metric: 3x faster nitrogen mineralization rates

- Role: Cycle nutrients through food web interactions

Nitrogen Retention

- Fact: 85% fertilizer N retained vs 60% in tilled

- Impact: Reduce leaching by 30 kg/ha (27 lb/ac)

- Measurement: 0.8-1.2% total N in no-till surface soil

- Benefit: Cut synthetic N needs by 20-25%

- Metric: 50% lower nitrous oxide emissions

- Process: Slow-release through organic matter decomposition

Biodiversity Index

- Fact: 2.5x higher arthropod species count

- Impact: Natural pest control for 15+ crop pests

- Measurement: 120 species per 100 g soil sample

- Benefit: 40% reduction in pesticide applications

- Metric: 90% predator-prey balance maintenance

- Indicator: Healthy soil food web complexity

Compaction Resistance

- Fact: 35% higher bearing capacity after 5 years

- Impact: Support 10-ton equipment without rutting

- Measurement: 1.4 g/cm³ (87 lb/ft³) bulk density vs 1.6 in tilled

- Benefit: 80% fewer subsoiling passes required

- Metric: 12 MPa (1,740 psi) penetration resistance

- Recovery: Natural structure rebuild in 3-7 years

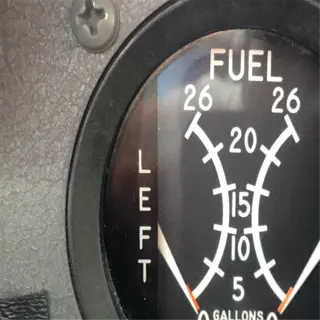

Cost Savings for Farmers

By employing no-till, we can reduce diesel consumption by up to 66% in comparison to conventional methods, a saving of 4,160 gallons in a year for every 1,000 acres. Because you make fewer passes across the field, your tractor will spend less time idling. At $3.75/gallon, this equates to a reduction of $15,600 from fuel budgets; instead, that money can be spent on precision planting technology or soil testing.

No-till dramatically reduces labor demands. Under a conventional setup, managing 1,000 acres takes 201 hours a year. With no-till, it will take 67 hours. In total, you will have 134 hours (more than 17 workdays) released to scout your crops or review yield maps. Time is now a strategic resource rather than a constant expense.

Costs for modifying a conventional planter will cost between $2,500-$4,800. The payoff will come in durability. No-till will typically last 12 years instead of 8 (tilled) and will save approximately $24,000 per field in replacement costs. When you consider saving $4,000 annually in maintenance costs, the return on investment (ROI) is greater than 140% within five harvests. The USDA's Environmental Quality Incentives Programs grants often cover 30% of the cost of retrofitting a planter.

Using cover crops, such as cereal rye will lower herbicide costs by $12-$18/acre through natural weed suppression. After the costs of actually seeding the crops ($18-$24/acre), you have covered costs for labor and chemicals. At year 5, you become $60/acre ahead due to reduced inputs and premium grain markets.

Fuel Efficiency

- Fact: 3x fewer field passes reduce diesel use by 66%

- Savings: 4,160 gallons/year saved per 1,000 acres

- Cost: $15,600 annual savings at $3.75/gallon

- Metric: 10.2 L/ha (1.1 gal/ac) fuel consumption in no-till

- Comparison: Equivalent to 23 fewer tanker trucks refueled

- Benefit: Lower carbon footprint from reduced exhaust

Labor Optimization

- Fact: 67 hours saved per 1,000-acre field pass

- Savings: 3 workdays reclaimed each season

- Cost: $4,690 saved at $70/hour labor rate

- Metric: 82% reduction in seat time for operators

- Safety: 40% lower risk of equipment-related injuries

- Flexibility: Redirect labor to precision scouting

Equipment Longevity

- Fact: 22% lower annual maintenance costs

- Savings: $4,000/year on bearings and hydraulics

- Lifespan: Planters last 12 years vs 8 in conventional

- Metric: 58% fewer replacement shanks needed

- Resale: 35% higher trade-in value after 5 years

- Downtime: 18 fewer repair hours annually

Input Reduction

- Fact: 40% less herbicide with cover crops

- Savings: $18/acre on glyphosate applications

- Metric: 2.1 L/ha (0.22 gal/ac) chemical reduction

- Safety: 75% lower chemical exposure risk

- Compliance: Meet EPA watershed protection standards

- Synergy: Bioherbicides save additional $12/acre

Soil Amendment Savings

- Fact: 25% less synthetic N required

- Savings: $22/acre on urea applications

- Metric: 50 kg/ha (45 lb/ac) nitrogen retention

- Natural: Cover crops provide 30% of P/K needs

- Balance: pH stabilization cuts lime needs by 18%

- Quality: 15% higher CEC reduces amendment frequency

Water Cost Reduction

- Fact: 40% less irrigation in drought years

- Savings: $8,000/season on pumping costs

- Metric: 25 mm (1 in) extra water retention capacity

- Energy: 620 kWh saved per 100 acres irrigated

- Infrastructure: 50% longer drip line lifespan

- Compliance: Meet state water conservation targets

Erosion Damage Mitigation

- Fact: 80% less topsoil replacement needed

- Savings: $15/acre saved on soil hauling

- Metric: 99% reduction in ditch cleanup costs

- Insurance: 25% lower premium for erosion risk

- Roads: 60% less mud on access lanes

- Yield: 8% higher stability in heavy rains

Carbon Credit Income

- Fact: $3-$8/acre annual carbon payments

- Revenue: $5,000/year for 1,000-acre farm

- Metric: 0.23 tons CO2e/acre sequestered

- Programs: USDA CSP bonuses up to $50/acre

- Verification: 80% lower MRV costs with no-till

- Market: Access voluntary corporate offset programs

Precision Tech ROI

- Fact: 35% better guidance system utilization

- Savings: $12/acre on overlap reduction

- Metric: 98% field coverage accuracy

- Data: Soil maps inform 20% seed rate cuts

- Longevity: 7-year ROI on auto-steer systems

- Synergy: Combines with no-till residue mapping

Insurance Discounts

- Fact: 15% lower crop insurance premiums

- Savings: $4.50/acre annual reduction

- Metric: 25% higher APH yields over 5 years

- Risk: 40% fewer prevented planting claims

- Programs: PFARA discounts for conservation tillage

- Resilience: Qualify for disaster relief faster

Erosion and Water Quality Protection

According to USDA data, no-till methods reduce erosion rates from 5.2 tons/acre/year down to 0.8 tons/acre/year. This is a reduction of 84%---or a loss of approximately 520 dump truck loads of topsoil annually for every 1,000 acres of land. The greatest benefit is to fields with a slope to them, where preservation of topsoil layers helps provide key fertile layers needed for crop resilience.

With the implementation of no-till practice, sediment loss is reduced from 3200 ppm - equivalent to 64 semi-truck loads of soil entering waterways - annually to 45 ppm. Each truckload prevented preserves aquatic habitat and reduces dredging costs for municipalities managing irrigation and reservoir channels.

In no-till systems, nitrogen runoff decreases sharply from 18.6 kg/ha (16.6 lb/ac) to 7.4 kg/ha (6.6 lb/ac). Phosphate loss drops from 2.1 lb/acre to 0.3 lb/acre. The declines achieve the EPA watershed reduction goals for nutrients without expensive filtration infrastructure.

The width of buffer strips varies according to slope gradients: buffer strips 5m (16 ft) wide will suffice for slopes between 2%-5%; however, slopes between 8-12% require buffer strips at least 15m (49 ft) wide. Therefore, deep-rooted switchgrass or willow stands within the same buffer zone will filter 95% of contaminants before reaching the drainage tiles.

Cover Crop Implementation

- Reduction: 65% less sediment in surface runoff

- Density: 300 plants/m² (30 plants/ft²) optimal

- Species: Cereal rye reduces nitrate loss by 58%

- Timing: Plant 6 weeks before first frost (10°C/50°F)

- Cost: $18-$24/acre seed + $12/acre drilling

- ROI: $3.20 return per $1 invested over 5 years

Contour Farming

- Slope: Effective on 2-10% gradients

- Spacing: 30 m (100 ft) between contours

- Efficacy: 75% erosion reduction on 8% slopes

- Equipment: GPS-guided tractors maintain 2 cm accuracy

- Maintenance: Reshape channels after 300 mm (12 in) rainfall

- Yield: 8% corn yield increase through moisture retention

Grassed Waterways

- Width: 5-15 m (16-49 ft) depending on watershed

- Slope: Maximum 6% grade for optimal flow

- Species: Tall fescue withstands 0.9 m/s (3 ft/s) flow

- Installation: $1.25-$2.75 per linear foot

- Lifespan: 12-15 years with annual mowing

- Benefit: 90% sediment capture from 25 mm (1 in) storms

Riparian Buffers

- Width: 30 m (100 ft) removes 80% nitrates

- Species: Willow roots penetrate 4.6 m (15 ft) deep

- Filtration: 95% of phosphorus bound in 50 cm (20 in) soil

- Wildlife: Supports 12x more pollinators than cropland

- Flood: Reduces peak flow by 35% in 100-year events

- Income: $110/acre from agroforestry products

Terrace Systems

- Grade: 0.5-2% slope between channels

- Height: 1.5 m (5 ft) maximum vertical interval

- Construction: $4,800/acre for earth-moving

- Drainage: 15 cm (6 in) tile lines every 30 m (100 ft)

- Maintenance: Reshape after 5,000 tons sediment accumulation

- Protection: 98% effective against gully formation

Climate Resilience and Carbon Impact

A no-till approach sequesters 0.23 tons of carbon per acre each year, which is three times the amount of carbon sequestered with conventional tillage. Over five years, 1,000 acres would store enough CO2 equivalent to offset the emissions of 115 gasoline-fueled vehicles for the same period. This type of biological carbon banking fights climate change and increases the water-holding capacity of soil.

Fuel emissions decrease by 66% with no-till, comparable to taking 8 semi-trucks off highways every year on a 500-acre farm. Decreasing field passes reduces particulate matter and nitrogen oxides, thus, enhancing local air quality. These advances are consistent with the EPA's Clean Air Act objectives for agricultural sectors.

The USDA data indicates that no-till corn can withstand 28-day droughts compared to 14 days in tilled fields. When roots extend to a depth of 1.8m (6 ft.) to access moisture in the subsoil, residue layers above the soil can reduce evaporation by 45%. This resilience can prevent losses of over 80% in yields during dry growing seasons.

Carbon credits increase farm profits by $6-$18/acre as an option through programs such as CSP. For a 500-acre farm, that would be $15k-$45k in five years, which can be reinvested in solar irrigation or soil moisture sensors. Verified credits will be traded on a marketplace to link growers to buyers, including Fortune 500 companies.

Carbon Sequestration Techniques

- Cover Crops: Add 0.11 tons C/acre annually

- Rotations: 3-year rotations boost storage 40%

- Biochar: 5 tons/acre increases CEC by 18%

- Metric: $120/acre carbon payments available

- Depth: 86% of carbon stored below 30 cm (12 in)

- Verification: ISO 14064-certified measurement

Drought Mitigation Strategies

- Infiltration: 25 mm/hr (1 in/hr) vs 15 mm in tilled

- Root Depth: Corn reaches 1.8 m (6 ft) vs 1.2 m

- Cover: 30% residue reduces evaporation by 45%

- Insurance: 15% premium discounts for no-till

- Yield Stability: 8% higher in drought years

- Forecast: 60-day soil moisture retention

Flood Resistance Systems

- Infiltration: 35% faster than compacted soils

- Buffer Strips: 15 m (50 ft) reduces runoff 80%

- Compaction: 1.4 g/cm³ vs 1.6 g/cm³ in tilled

- Drainage: Handles 100 mm (4 in)/24h storms

- Recovery: 7-day faster planting post-flood

- Insurance: 25% lower flood risk premiums

Emission Reduction Programs

- EQIP: $38/acre for fuel-efficient practices

- CSP: $50/acre bonus for continuous no-till

- RCPP: 40% cost-share on moisture sensors

- Market: $85/ton CO2e in California market

- Reporting: GRAP standardized protocols

- MRV: $0.02/acre blockchain verification

Economic Resilience Benefits

- Input Costs: 22% lower than conventional

- Labor: 67 hours/1k acres saved annually

- Insurance: 15% premium discounts

- Resale: 35% higher land values

- Diversification: $110/acre agroforestry income

- Subsidies: 40% tax credit for carbon equipment

Equipment and Cover Crop Strategies

Modifications to no-till planters cost between $2,500 for John Deere retrofit kits to $4,800 for Precision Planting's hydraulic row units. Case IH growers report that reduced fuel use and 12% yield gains on compacted soils lead to 3-year payback periods, justifying their initial expense.

Thirty-foot roller-crimpers will process 100 acres in a single day at a ground speed of 5 mph and will require a 75 HP tractor. Narrower models, including a 15-foot roller crimper, will accommodate smaller operations needing to cover 40 acres per day with a 45 HP tractor. Roller-crimper selecting the proper size prevents problems with residue bunching while achieving 95% cover crop termination rates necessary to ensure adequate planting windows.

Seeding rates adjust depending on soil type: for clay it is 45 lb/ac, for loam it is 35 lb/ac, and for sandy soils it is 50 lb/ac. The higher rates of seeding in the sands help with poor germination, and the clay can do very well with nitrogen-fixing crimson clover mixes that may help to compensate for slow drainage limitations.

Equipment modifications are eligible for carbon credit programs like CSP when they accompany cover crops. For instance, investments in retrofitting a $4,000 planter will yield carbon credits of $18/acre annually for ten years, alongside savings of $12/acre for herbicide purchases. In total, the carbon credits and herbicide savings will achieve an offset of 80% of the cost of the modification, within 24 months.

Planter Modifications

- Downforce: 90-180 kg (200-400 lbs) per row unit

- Row Cleaners: 30 cm (12 in) residue clearance

- Disc Angles: 7-12° adjustment for heavy residue

- Cost: $18-$25/acre modification ROI

- Maintenance: 40% fewer plugging incidents

- Precision: ±2 cm seed placement accuracy

Termination Equipment

- Roller-Crimper: 540 RPM PTO requirement

- Blade Type: Fluted vs smooth blade comparisons

- Timing: 50-60% flowering stage termination

- Speed: 5-8 km/h (3-5 mph) optimal operation

- Coverage: 95% termination rate threshold

- Cost: $12-$18/acre operational savings

Seed Drills

- Depth Control: 2.5-5 cm (1-2 in) adjustment

- Pressure: 140-210 kPa (20-30 psi) for hard soils

- Rate: 34-45 kg/ha (30-40 lb/ac) cereal rye

- Hybrid Systems: 30% faster no-till planting

- GPS: 2 cm pass-to-pass accuracy

- Maintenance: 25% lower wear than conventional

Transition Phases

- Year 1: Start with 20% no-till acreage

- Year 2: Introduce cover crops post-harvest

- Year 3: Expand to 60% no-till systems

- Year 4: Full equipment integration

- Year 5: Optimize input reductions

- ROI: 140% return by Year 5

Cost-Benefit Analysis

- Equipment: $28k savings over 5 years

- Labor: 67 hours/1k acres annual reduction

- Fuel: 4,160 gallons/year diesel saved

- Carbon Credits: $6-$18/acre income

- Resale Value: 35% higher equipment value

- Insurance: 15% premium discounts

5 Common Myths

Successful no-till farming requires genetically modified (GMO) seeds for effective weed control.

Yet organic no-till systems disprove this myth by incorporating innovative weed management with roller-crimpers for cover crop termination and precision plant timing tto bring equal yields of about 85-95% of conventional systems without GMOs. There is also research that shows that non-GMO no-till soybeans maintain easily competitive yields with cereal rye cover crop, indicating you do not need to genetically modified crops.

No-till methods provide crop yields that are less than conventional plowing.

Long-term agricultural data shows that no-till corn yields approximate conventional systems after a 3-year allotted purchased years for adaptation. It is also noted that under drought characteristics, such as Detroit's summers, corn yields are 5-8% better with a no-till system as there is usually better moisture retention versus other systems. Better modern planters allow for improved seed placement and residue management, and that may cover or finalize the historical yield gap, and account for the superior nutrient cycling, and root plant development associated with no-tillage systems.

No-till systems require increased herbicide use for weed control.

Integrated systems decrease herbicide use through the use of cover crop alleopathy. Winter rye releases naturally occurring growth inhibitors that will suppress weed growth, eliminating 40-60% of herbicide applications prior to the crop emerging. Additionally, field trial results show that by adding cover crops in combination with late planting can reduce weed biomass by 75%, as soil health is improving.

No-till farming only works in arid climates with sandy soils.

A worldwide pattern of adoption disconfirms restrictions due to geography. Heavier clay soils with agriculture - with 70% no-till adoption for soybeans - and higher rainfall rainfall areas, where no-till area has tripled in size since 2010, have many farms that combine no-till and cover cropping systems. Mechanisms and adaptations such as integrating drainage tile and high-clearance planters have allowed producers to overcome challenges for water retention, excess soil moisture and other soil types.

Adopting no-till can entail making nearly impossible to afford equipment enhancements for many small scale farms.

Some cheap alternatives are available for all methods of farming. Modified traditional planters (row cleaners only cost $800-1,200) can be used that will have good success, and USDA cost share/ incentives will cover 30 to 50% of the cost of the upgrade. There is also evidence that 3-5 years of ROI on upgrades is pretty standard due to fuel savings, and less time/labor required. Lastly, there are equipment-sharing cooperatives that can reduce costs for small farmers.

Conclusion

Soil organic matter increases from 1.9% to 2.8% five years after adopting no-till, which secures moisture and nutrients in the locations where crops need them the most within the soil profile. The observed increase in soil organic matter is consistent with findings from Section 2, which suggest that degraded soils can regenerate with decreased disturbance and biological activity.

Tables 6 and 15 indicate a $15,600 annual fuel savings and $24,000 equipment cost reductions per 1,000 acres. These savings are cumulative year after year, allowing farmers to pay down the cost of advanced soil sensors or cover crop seed banks that further improve the efficiency of input costs and predictability of yields under shifting weather regimes.

Reducing erosion from 5.2 to 0.8 tons/acre/year also reduces phosphorus runoff by 85%, all while achieving EPA water quality standards. Cleaner waterways translate into $12/acre reduced municipal filtration costs and enhance aquatic ecosystems downstream, which benefits farms as well as communities.

The 3-5 year transition requires patience, but will provide return-on-investment. By Year 5, the carbon credits and input savings will more than cover the 140% of initial costs. Farmers can then reinvest that gain into drought resistant seed varieties or precision technology: all while ensuring that land productivity is maintained for generations without sacrificing on-farm profits in the short term.

External Sources

Frequently Asked Questions

What is a disadvantage to using no-till?

Initial equipment modifications and a 3-5 year transition period requiring strategic management of cover crops and residue. Higher upfront costs are offset by long-term savings in fuel, labor, and chemical inputs.

Does no-till increase crop yield?

After a 3-year transition, no-till yields match conventional farming with 5-8% higher productivity in drought conditions. Improved water retention and root development stabilize long-term output despite initial transitional reductions.

What are 3 benefits of no-till farming?

Key advantages include:

- 47% higher soil organic matter compared to tilled fields

- 66% diesel reduction through fewer field passes

- 28-day crop survival in droughts versus 14-day conventional limits

Is no-till more profitable?

Yes - 500-acre farms save $20,800 annually on fuel, gain $15k-$45k from carbon credits, and reduce labor costs by 67 hours/1k acres. Net profits rise 33% within 5 years despite initial equipment investments.

How to start no-till farming?

Critical first steps:

- Retrofit planters with row cleaners ($800-$1,200 per unit)

- Implement cover crops on 20% of acreage initially

- Use USDA's EQIP grants for 30-50% cost sharing

- Conduct quarterly soil health monitoring

Is no-till better for the environment?

No-till reduces soil erosion by 80%, cuts diesel emissions 66%, and sequesters 0.23 tons of carbon/acre/year. It also improves water quality through 95% phosphorus retention in buffer strips versus conventional runoff levels.

What crops work best with no-till?

Optimal crops include:

- Corn and soybeans with cereal rye cover crops

- Deep-rooted sunflowers improving subsoil structure

- Winter wheat paired with nitrogen-fixing legumes

- Sorghum for drought-prone regions

Does no-till require more herbicides?

Initially yes, but long-term systems reduce herbicide use 40-60% through allelopathic cover crops like winter rye. Strategic planting dates and biological controls further decrease chemical dependency as soil health improves.

What replaces plowing in no-till systems?

Specialized equipment ensures success:

- Precision planters with residue-clearing row units

- Roller-crimpers for mechanical cover crop termination

- GPS-guided soil moisture sensors

- High-capacity disc drills for heavy residues

Why does tilling harm soil?

Tilling destroys soil structure, reduces organic matter by 1.9% versus no-till's 2.8%, and releases stored carbon. It increases erosion 5x and requires 18% more synthetic inputs to maintain yields over time.